In case your eCommerce enterprise makes use of a warehouse for storage and distribution of products, optimizing the warehouse is important. By implementing the correct expertise, design, and processes, companies can enhance the effectivity and effectiveness of their warehouse operations, leading to value financial savings, improved buyer satisfaction, and elevated competitiveness.

The eCommerceFuel Discussion board has greater than 300 threads about constructing, managing, and optimizing warehouses. We’ve distilled among the greatest actionable recommendation that can assist you construct and optimize your warehouse.

Designing an Environment friendly Warehouse

Warehouse Structure Instruments

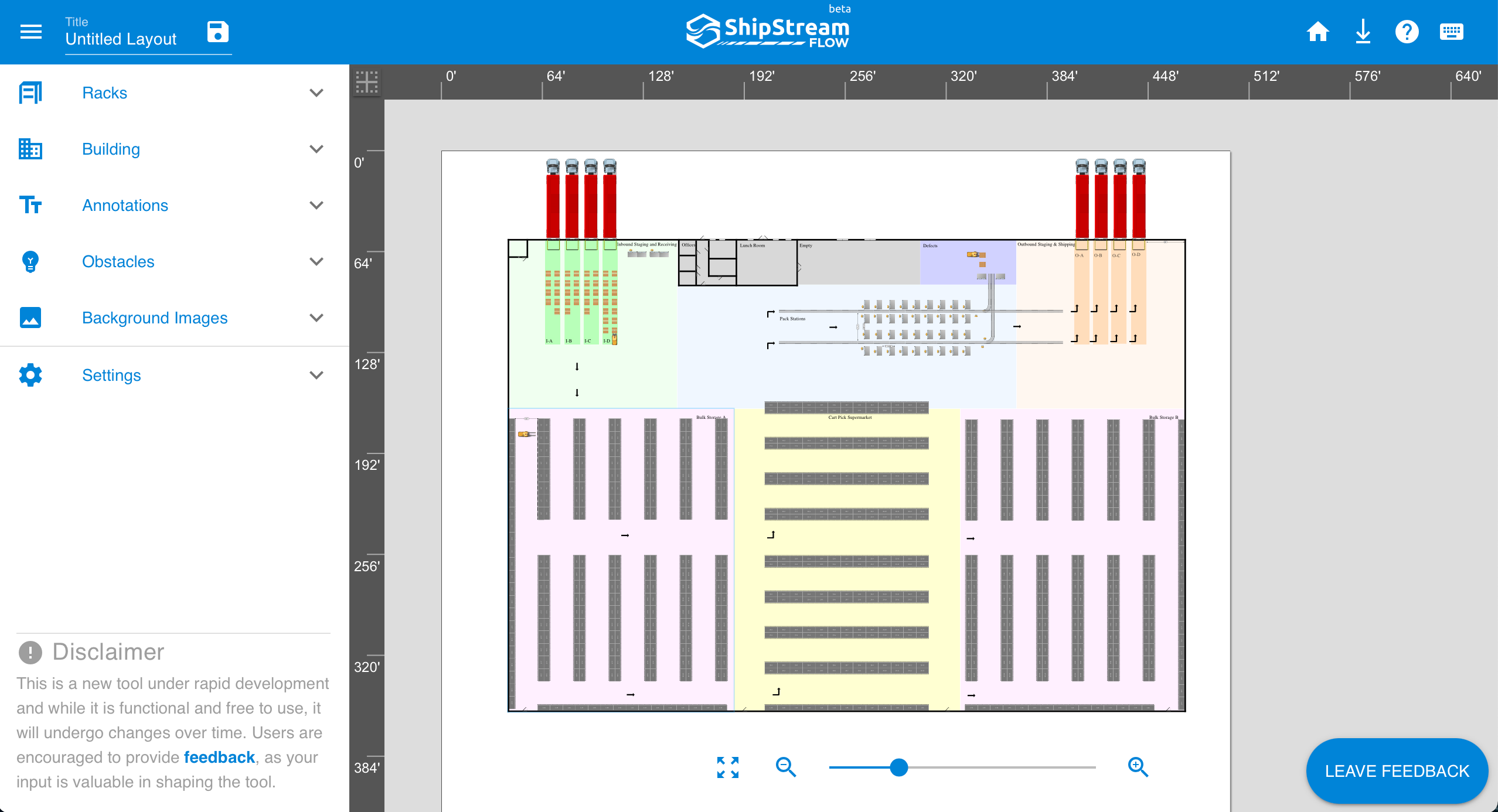

When designing the structure of your house, the eCommerceFuel group recommends modeling your wants and constraints upfront – and the simplest approach to take action is with pc aided design (CAD).

AutoCAD is the gold commonplace and can enable for the best stage of element, however the studying curve might be steep for learners. In the event you solely want primary performance, ShipStream offers a free software referred to as Move particularly designed to assist design your warehouse structure, and SmartDraw’s browser-based design software options an approachable interface with out compromising core options.

Move by ShipStream is a free warehouse design software

One other risk, in the event you’re beginning with a clean canvas, is to go to the location with just a few rolls of tape and begin marking out your rack places on the bottom. After marking all the things with tape, members suggest transferring these measurements to a digital design to keep away from errors within the execution of your plan.

Enhance Warehouse Effectivity with Structure Evaluation

The easiest way to enhance productiveness is to observe your warehouse in motion.

Watch your workers, and even work just a few shifts – when and why do they go away their stations? Are there objects that they steadily should stroll away for? How are you going to carry these things nearer and reduce these wasted walks?

One discussion board member offers a superb information for enhancing warehouse effectivity by way of structure evaluation. To research your structure set up some cameras, you then or your warehouse supervisor spends a complete day watching the cameras and recording what number of instances your shippers go away the transport space. You’ll be able to report the place they went, what they wanted, and what number of steps they took. Then on the finish of the day take your outcomes and create a warmth map.

“My aim with that is for our shippers to do their decide listing within the morning and actually by no means go away the transport space the remainder of the day. In reality we have now a whiteboard proper by the door to depart that claims “What do you want?” in different phrases write down what your going to go get in the course of the day. We then take this listing and optimize (as a result of issues will come up). You’re going to take your warmth map and use that in your Water Spigot.”

“A Water Spigot is a piece of your transport space that’s solely stocked with objects which are wanted the entire time. The most popular a part of your warmth map (the objects they had been at all times strolling to get) take these objects and put within the Water Spigot space within the transport space. It ought to be shut and straightforward on your shippers. Actually, 5 steps away and so they have it. You’ll kick your self as you notice a few of your commonest issues are on the opposite finish of the warehouse.”

Optimizing the structure of a warehouse is a endless activity so don’t attempt to create the “good” structure. As an alternative, if you can also make a few enhancements this week try this instantly and see what occurs. Then make just a few extra adjustments subsequent week and so forth.

Bettering Warehouse Storage

In the event you assume you’ve run out of room, likelihood is you haven’t. In lots of instances, one of the best ways to go is up – benefit from any vertical house you may have, and use the ground financial savings to suit extra stations, racks, or tools.

In the event you maintain any stock, you want a shelving/rack system. The quantity and configuration of those racks is set by:

- Product – What are the scale of your SKUs? Are your merchandise assembled on-site, or do they arrive able to ship?

- Course of – Is stock palletized and, if that’s the case, in what dimensions? How a lot will every pallet weight? How will your workers entry these things? Will they want specialised tools?

- Area – What number of aisles can you slot in your warehouse house? What number of do you want? How tall are the ceilings? With excessive sufficient ceilings, some members have discovered success with a Very Slim Aisle (VNA) structure, which utilitizes taller storage models and specialised tools for max productiveness in a given house.

One in every of our members offers some extra issues for choosing pallet racks:

- Add wiggle room to your commonplace measurement pallet. Say your commonplace pallet is 40″ huge (fork aspect) x 42″ lengthy. Somebody might suggest a 120″ beam which at first look sounds okay, 40*3 = 120. However that received’t work except you rent forklift gods since you want slightly wiggle room. So now you go from 3 slots to 2 slots all as a result of the rack isn’t 124″ as an alternative of 120″.

- Dense aisles improve tools prices. Your aisle measurement impacts the forklift you’ll choose. You possibly can double or triple your warehouse slot capability by going from 13 toes (which inserts the standard sit down elevate) to 60 inches (VNA). However that requires a $50k forklift as an alternative of a $8k forklift. Does the additional density pay for the dearer elevate?

- Heavy pallets require examine infrastructure. How heavy are your merchandise? Now we have pallets which are 3,000 kilos and pallets which are 500 kilos. The heavier the load the bigger beams (3, 4 or 6 inch) you’ll want to make use of in your warehouse. A bigger beam is after all dearer and takes up extra vertical peak.

After answering these questions and figuring out your specification necessities, use your chosen design software to prototype the rack structure.

The group recommends the next sources for buying pallet racks:

- Craigslist – Will be hit and miss, relying in your native market

- Bidspotter.com – On-line auctions, bigger heaps are sometimes bundled and logistics of eradicating from vendor’s warehouse might be tough

- WarehouseRack.com and Materials Dealing with Change – Giant on-line resellers of recent and used racking methods

As your aisles begin to develop and fill, it’s essential to have a exact technique of location identification. A member shared this Location Quantity information from Warehouse Coach that explains an alphanumeric location labeling system that may simply be built-in into your present processes and shortly enhance warehouse effectivity

Stations

The design of your packing and transport stations will rely in your SKUs and course of, however the group has just a few ideas to assist streamline your warehouse operations:

- Maintain the work space fully freed from instruments, tools, trash, and so forth, and use magnets or a pegboard to maintain instruments close by with out cluttering the workspace.

- Combine cameras into the station to assist with course of management, high quality assurance, and buyer disputes

- Ensure that your work areas are adequately local weather managed – workers which are too scorching/too chilly might be much less environment friendly

- Construct a scale into the packing station

- Take into account HDPE (a sort of plastic) on your tabletops – it’s extraordinarily sturdy, simple to keep up, and ideal for sliding packages round

ECF members frequently publish photographs and video demos of their customized packing stations. In the event you’re an eCommerce service provider take into account making use of.

Warehouse Operations

Warehouse Administration Software program

To maximise warehouse effectivity, scale back scale back errors, and streamline operations, your corporation wants the correct software program. A few of the ECF group’s strategies for stock and warehouse administration embrace:

ShipHero Warehouse Administration System

Based by an ECF member, this digital resolution consists of order monitoring, stock administration capabilities, cell barcode scanning, price comparisons, and automatic reporting

Stock-Planner.com

Complement your stock administration with automated forecasting and buying

ShippingEasy

Low cost, light-weight resolution with barcode scanner integration

Linnworks and Extensiv (previously Skubana)

Standard group suggestions for built-in stock /order administration

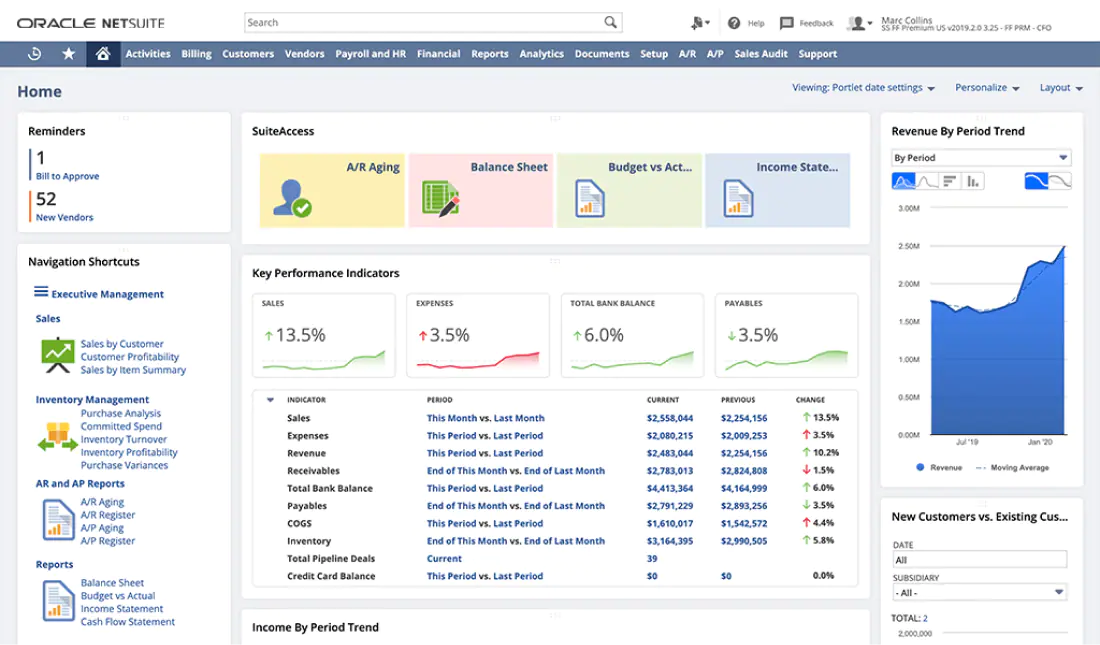

Enterprise Useful resource Planning (ERP) Software program

Enterprise useful resource planning (ERP) software program is one other kind of warehouse administration system that act as a connective tissue between disparate silos of data and processes. An ECF member explains:

“An ERP is accounting software program first. It’s all about with the ability to observe the place each single greenback, each incoming and outgoing. The profit is that all the things inside your corporation might be and is tied collectively from a monetary perspective.

Every little thing is what it’s. It removes the “Simply do it” and makes you set one thing within the ERP system to indicate what you probably did, or else your numbers are off. Then when your numbers are off, you get to determine why and “Simply do it,” goes away since you don’t understand how lengthy it took or how a lot cash it value. There turns into a transaction or journal entry for LITERALLY EVERYTHING.”

Usually, companies with decrease quantity or fewer particular person SKUs are much less prone to want ERP integration, whereas these with bigger and extra advanced operations have the ability to justify the massive funding of each time and capital to get arrange.

Perceive Your Core Course of: Choose & Pack

“Choose and Pack” is the central strategy of order achievement:

- An order is obtained

- The SKUs in that order are positioned and pulled from storage, and assembled into a whole order (Choose)

- The assembled objects are positioned into their transport containers with any obligatory void filler and sealed/labeled (Pack)

Giant operations are inclined to separate their warehouse personnel into Pickers and Packers, however in smaller operations these could also be mixed right into a single function.

In both case, the most-recommended system improve for decide/pack is a barcode scanning system. Many warehouse administration methods natively combine with barcode methods, and members virtually universally discover that they scale back each errors and achievement instances. The gold commonplace of barcode methods is the worldwide GS1 group, which points and manages the UPC codes printed on practically each retail merchandise on the market within the US.

Different course of ideas from ECF members embrace:

- Movie all the things

- Forestall packers from speaking to one another

- Implement not less than one high quality management verify – no order ought to go away the warehouse with out being checked by somebody aside from the packer

- Doc your processes with an ordinary working process (SOP). Along with offering a singular “supply of reality” for coaching workers, creating the doc itself will pressure you to outline each a part of your system

- Observe all the things, each with onerous knowledge within the type of KPIs and with cameras

Key Efficiency Indicators (KPIs) for Warehouse Effectivity

One in every of our members shared some warehouse effectivity ideas from a high-level dialogue on key efficiency indicators (KPIS):

“One constant theme was a want to maneuver from lagging indicators to main indicators. Many KPIs are “rear view window” and should not have predictive worth. One presenter, who’s in a fast development stage that’s solely constrained by money movement, used historic KPI values and a spreadsheet to foretell and handle development price (principally how a lot to put money into promoting and the ensuing impacts on money wants).

The vary of instruments used to collect and current metrics had been huge. They ranged from spreadsheets, to energy factors, to built-in software program. Instruments proven had been Fathom , which had a pleasant drill down and visualization functionality and LivePlan which was properly built-in with QBO and had good charting options and BeProfit a Shopify app.

The “proper” KPIs for the enterprise are very depending on what life cycle stage the enterprise is at. Two of the companies had been round fairly some time, had been nonetheless rising, however within the “Optimize” stage and the KPIs had been targeted on discovering incremental efficiency enhancements. Different companies had been in (virtually chaotic) uber development phases and so they had been targeted far more on huge macro KPIs. Extra particularly, there have been two broad classes of KPIs: operational and advertising and marketing. Advertising and marketing had been gross sales, promoting, and conversion oriented. Operational included fulfilment, customer support, and stock KPIs.”

Another knowledge factors that members suggest monitoring in your warehouse:

Order Processing Prices

In value per bundle, really helpful benchmarks change based mostly on the scale and amount of things in every bundle.

One ECF member was in a position to ship ~30,000, small, low-quantity packages at an all-in value of about $1.40.

Success Pace, Order Accuracy, & Stock Accuracy

Pace is one other essential metric for warehouse managers, however make sure you observe order and stock accuracy in tandem or danger workers prioritizing pace at the price of errors.

Utilizing a novel incentive program, one member of the group was in a position to ship a “fully custom-made product at a price 62% YoY at 100% per day with a 12pm lower off” throughout his peak season.

Stock Ranges

One member, whose enterprise generates over $25 million per 12 months, recommends measuring Gross Margin Return on Funding, Flip and Earn, and Direct Product Revenue. He additionally shares his firm’s doc detailing the processes behind every of those metrics within the boards.

Staffing a Warehouse

Roles

One member recommends defining roles in your warehouse operations by structuring based mostly on positions, not folks:

- We wrote out all of our obligations we had in our firm.

- I created an Org Chart based mostly upon positions. “OK we want an Ops individual, we want a Warehouse Supervisor, we want 3 shippers, we want…”. This was tough to do however I pressured myself to not take into consideration PEOPLE however the precise POSITION. This requires you to be analytical and never emotional.

- Then in every of these positions we listed out key abilities wanted and key metrics for every place that would wish to hit.

- Then I principally re interviewed my total staff and had them apply for every place. We legit had interviews and so they confirmed up dressed up good and utilized for sure positions we thought they’d be good at. We had character profiles carried out so we knew if it was a great match. There was numerous phycological advantages to doing this in addition to it was clear we had been altering how we do issues.

- Throughout that evaluation interval we had a scorecard for every place and function after which we rated every individual on the abilities wanted and the way we thought they’d do on every of the important thing metrics.

- We moved folks round to the positions that had been greatest fitted to them and turned them unfastened. The subsequent quarter was superb and so they thrived.

- By doing this the losers had no the place to run. Everybody had key roles they wanted to carry out in. Inside 6 months we went from 25 workers to 18 and our staff thrived or surged once more. It was loopy to me that while you take away the bags workers the way it causes everybody to be extra productive and love coming to work that rather more.

Interviewing

The extra successfully you’ll be able to display screen potential warehouse staff within the early stage, the extra time you save interviewing dangerous suits. A straightforward approach to do that is to require a easy query in your job utility. One member suggests the next:

“If , please reply by electronic mail along with your resume or work historical past and full this sentence:

“I’m the proper selection for this part-time place as a result of …”Over half of our candidates don’t reply the query and I really feel that these are the individuals who I don’t need to work with as a result of they don’t need to do one additional step or they’re unable to comply with directions.”

Retention

Good workers aren’t solely a fortunate discover, however a big funding, and also you need to be certain they stick round. An ECF member shares how warehouse managers can incentivize development of their staff:

“I’ve discovered that small frequent pay will increase for taking up extra duty and studying extra concerning the operations of the enterprise has constructed a system that encourages guys to continue learning. Usually when guys have hit the highest of the warehouse place they ask “so what else can I tackle” which is basically cool.”

Most members additionally counsel some kind of incentive pay – determine your required end result, then reverse engineer the proverbial carrot that rewards that end result. That is additionally a possibility to experiment and get artistic. As an alternative of providing solely an ordinary quarterly or yearly bonus, for instance, one member guarantees his workers a every day money bonus for assembly efficiency targets. By taking part in into the human tendency to worth immediacy, he’s discovered that smaller, extra frequent incentive pay has larger return in warehouse productiveness than a bigger bonus promised sooner or later. One other member provides:

“So far as incentives it’s essential to not simply base it on one factor, as a result of then the staff will maximize that one factor. So if you’re going to base it off of orders shipped per hour you then higher have accuracy as some variable in there too”

Last Ideas: Bettering Warehouse Effectivity

In the event you run an eCommerce enterprise and deal with your individual achievement, optimizing the warehouse is important.

All of it begins with the correct warehouse design paired with the correct software program to maximise the warehouse effectivity. Upon getting the warehouse setup it’s time to observe processes, optimize stations, implement KPIs, and rent the correct staff.

When you may have a clean and environment friendly warehouse you’ll have the ability to decrease your prices, enhance buyer satisfaction, and scale back complications.

Study Extra within the Boards

We publish the total guides within the eCommerceFuel Discussion board. The complete model in our non-public member discussion board is full of real-world benchmarks, photographs and movies of warehouses and operational setups, and much more detailed technique strategies.

Along with reside and digital networking alternatives by different entrepreneurs around the globe, ECF members achieve entry to proprietary course of paperwork and video walkthroughs, provider critiques and suggestions, and hard-won ideas and tips, all shared freely with fellow group members by completed retailer house owners.

To hitch, potential new members should personal an eCommerce retailer with $1 million or extra in annual income, and the appliance might be discovered right here: Apply to Be part of eCommerceFuel