The numerous development of cloud computing has made it simpler and inexpensive for companies in all industries to scale their software program functions. Nonetheless, with the rising use of massive information, the demand for organizations to speculate money and time into scaling their software program can be rising.

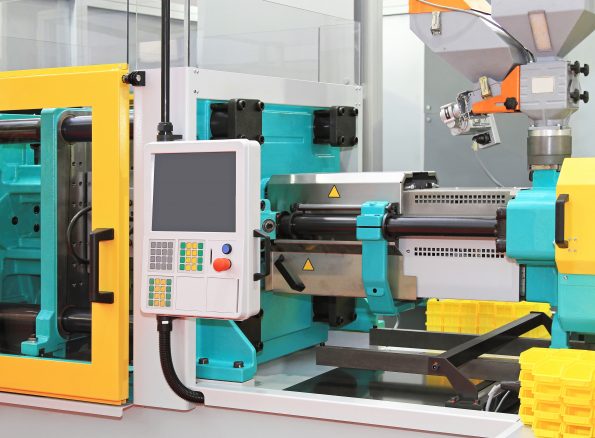

Injection moulding machine for plastic components manufacturing

If it doesn’t scale its ERP system, a plastic manufacturing unit can danger software program efficiency points, like dropped connections or gradual repose. This text discusses the Plastic Manufacturing ERP scalability firms can encounter when their workforce and information factors increase past expectations.

Why Ought to Your ERP Software program Be Scalable?

Earlier than discovering the challenges it is advisable overcome when scaling the plastic manufacturing industry-specific ERP, you need to know the significance of scalability.

Merely put, scalability is outlined because the system’s potential to develop or cut back capability and performance based on person demand. In case your ERP software program is scalable, it will likely be highly effective sufficient to remain secure, even throughout upgrades, adjustments, or useful resource reductions. With out elastic ERP software program within the plastic manufacturing unit, supporting development can turn out to be tough, and it might have an effect on the person expertise.

Challenges of Plastic Manufacturing ERP Scalability

Right here listed are widespread roadblocks {that a} plastic manufacturing firm should overcome when incorporating scalability into the ERP strategy.

Non-aligned know-how plan and technique

Earlier than evaluating distributors, the challenge group should begin with the pre-implementation planning section. Whereas it’s inconceivable to find out the place your plastic manufacturing facility will probably be within the subsequent 5 to 10 years, you should use present information to make pretty correct projections. Take a look at all eventualities that would have an effect on the corporate’s development and what instruments your group would possibly want sooner or later.

You shouldn’t begin formulating a tech plan with no roadmap. Doing so will result in the funding in ERP software program assembly your rapid, short-term wants. And as your organization develop, you would possibly work out that the software program not serves the enterprise because it did earlier than.

Underestimating the enterprise and purposeful necessities

Not having a transparent understanding of how your plastic manufacturing unit plans to make use of the ERP, you may be unable to emphasise scalability. It’s particularly true when the corporate is within the infancy stage. Sc scope creep can often happen when an organization doesn’t prioritize software program scalability. You would possibly deploy an off-the-shelf integration however notice that your organization wants extra superior performance past the preliminary request.

You would possibly notice all this throughout the last testing section and even after the go-live date. After which you’ll have solely two options-

- Adapt by letting semi-manual processes work round flaws

- Pay for ongoing enhancements as and when your organization encounter points or faults.

These options will waste your beneficial time and funds, leading to decrease productiveness.

Too many gamers

The bigger your plastic manufacturing firm software program community, the extra gamers will probably be concerned, together with software program suppliers, consultants, integrators, growth consultants, and extra. Whereas all these professionals may help when juggling with manufacturing challenge, it could actually make it tough to determine precisely the place scalability problem is happening and who can remedy it.

Generally, the plastic manufacturing unit can’t keep away from having a number of software program programs. The important thing to stopping ERP failures in such a state of affairs is to get every participant to acknowledge his duty and determine potential points at a sooner tempo.

Speaking scalability wants with the seller

Think about scheduling conversations with potential distributors when planning to implement a brand new ERP software program. Ask if the software program is scalable and versatile sufficient to work with future programs and accommodate the most recent integrations with enterprise growth. Furthermore, ask for the seller’s availability and assist within the longer run.

Last Ideas

With a lot information passing by way of in plastic manufacturing organizations on an ongoing foundation, you want ERP software program that’s versatile sufficient to maintain up. It’s essential for the software program to serve a number of units and information streams at any given time.

Nonetheless, the problem lies in anticipating the issues or choices a producer should take into account to make sure system agility. Your organization can keep away from many challenges of the ERP for Manufacturing Firm scalability with correct planning. By making ready for future enterprise development, you’ll know the options and capabilities you want within the ERP for at present and the long run.

The submit What Challenges of ERP Scalability Does a Plastic Manufacturing Firm Have to Overcome? appeared first on The Startup Journal.